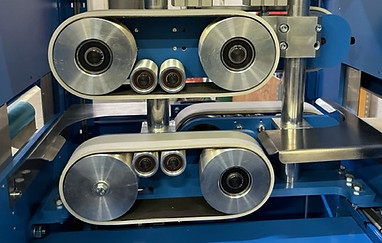

BELTS & PADS HAUL OFFS

Two-caterpillar belt or pad haul-offs characterised by their robustness and versatility.

Oversized input / output chassis beams and sheet-metal to obtain the greatest possible stability in operation.

No column, upper caterpillar held in place by two cylinders at input and output to allow very wide formed sections to pass through.

Direct drive with an asynchronous geared motor mounted on each caterpillar’s axle. No maintenance.

Three possible types of control :

- Remote control desk

- Control on the front face

- Synchronous link with extruder desk

Pressure / counter-pressure setting on the upper caterpillar for thin-wall tubes and formed-sections. Poly-V belts and pad quick-change system as an option.

For both versions, we can propose a large range of contact lengths and widths, min. and max. linear speeds as well as haul-off forces with associated torque.

All our chassis are precision-welded in order to guarantee overall stability.

OVERALL :

2-track haul off with skids or belts for in-line extrusion of plastic profiles or tubes

Simple to use, robust, versatile, compact and easy to maintain

BENEFITS:

-

No column, wide passage possible up to 600mm

-

Remote control

-

Oscillating system

-

Compact welded structure

-

Direct drive by asynchronous geared motor on each track

-

Improved accessibility

-

Reduced footprint. Electrical cabinet integrated into the frame

OPTIONS :

• Choice of pad shape, colour and hardness

• Pads with quick-change system

• Pressure / counter-pressure adjustment on input

• Choice of material for belts

• Poly-V belts for great haul-off force

• Touchscreen control

• Input / output safety hatch

• Second variable-frequency drive

All configurations can be made to suit your specific requirements